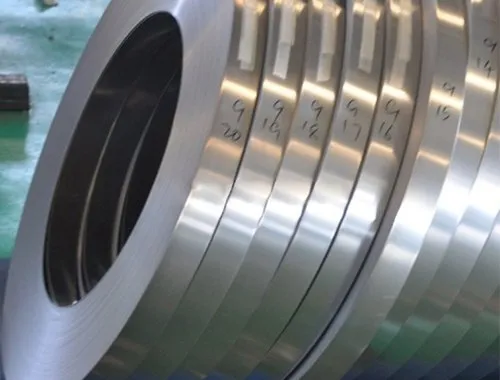

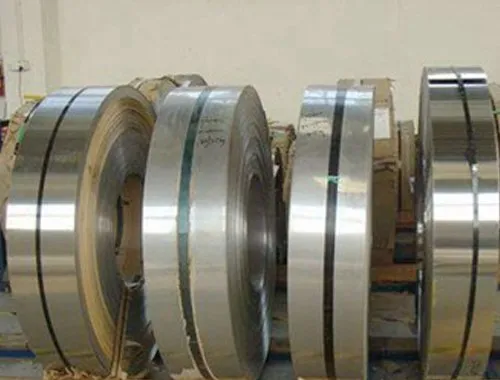

ASTM A240 301 1/4 Hard Strips, ASTM A240 301 Half Hard Strips, JIS SUS301 Hot Rolled (HR) Strip, AISI 301 1/2 Hard Strips, UNS S30100 Hard Winding Strip, 301 Quarter Hard Strips, 301 3/4 Hard Strips, AISI 301 Hard Strip, EN 1.4310 Cold Rolled (CR) Strip.

301 stainless steel strips have found their application across industries due to their excellent mechanical strength, corrosion resistance, and ability to withstand high temperatures. These strips are produced in multiple dimensions and forms based on specific application requirements. The production process involves heat treating the steels which gives them properties similar to carbon steel strips in structural strength, but with some environmental resistance.

Being an austenitic grade, 301 stainless steel has the distinct advantage of combined strength with formability. It can be cold worked to increase its tensile strength without requiring added heat treatment. Such characteristics make it favorable for use where high durability and flexibility is required which makes these strips suitable for a number of industries.

The most remarkable characteristic of the 301 stainless steel strips is that they are non-magnetic in the annealed condition. In addition to being non-magnetic, they possess beneficial electromagnetic properties such as magnetic permeability and electrical conductivity. These features are very advantageous for industries like food processing, chemical plants, medical sectors, and electrical work. Their applications include shafts, brackets, springs, and other precision components which demand high strength and stability.

The starting materials used to produce these stainless steel strips along with the advanced machinery utilized result in uniform finishing and accuracy ensuring a steady aesthetic polish alongside exact dimensions. Various levels of hardness including quarter hard, half hard, three-quarter, full hard, and extra hard offer a wide array of fabrication targets as well as operational requirements. Performance wise alongside quality offering competitive pricing has ensured 301 stainless steel strips remain a preferred material in many modern industrial applications.

SS 301 Strips Specification

| Product | Stainless Steel 301 Strips |

| Standards | ASTM A240 / ASME SA240, JIS, AISI, GB, DIN, EN, etc. |

| Thickness | 0.025 to 3 mm and as per Customer Requirement. |

| Width | 3 mm to 2000 mm and as per Customer Requirement. |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, as per Customer Requirement. |

| Hardness | Full Hard, 1/2 hard or Half Hard, 1/4 Hard or Quarter Hard, Soft or Annealed, 3/4 Hard, Spring Hard, Rolled. |

| Surface Finish | NO.4, 8K, Brush, Cold rolled (CR), NO.8, SATIN, 2B, NO.1, Etching, Hot rolled (HR), Hair Line, 2D, BA, Galvanized, Sand Blast, Checkered, Plastic Coated, Embossed, Mirror Finish etc. |

| Brand: | US Origin, Japanese Origin, Korea Origin, Thailand Origin, European Origin, Indian Origin. |

| Manufacturer: | Arcelor Mittal, Nippon Metal, Outokumpu, Aperam, Jindal Stainless, Thyssenkrup, Baosteel, DKC Korea, VDM, TISCO, POSCO. |

| Test Certificate | Hydrostatic test, Radiography test, Impact test, Chemical test, Macro and Micro-test, etc. |

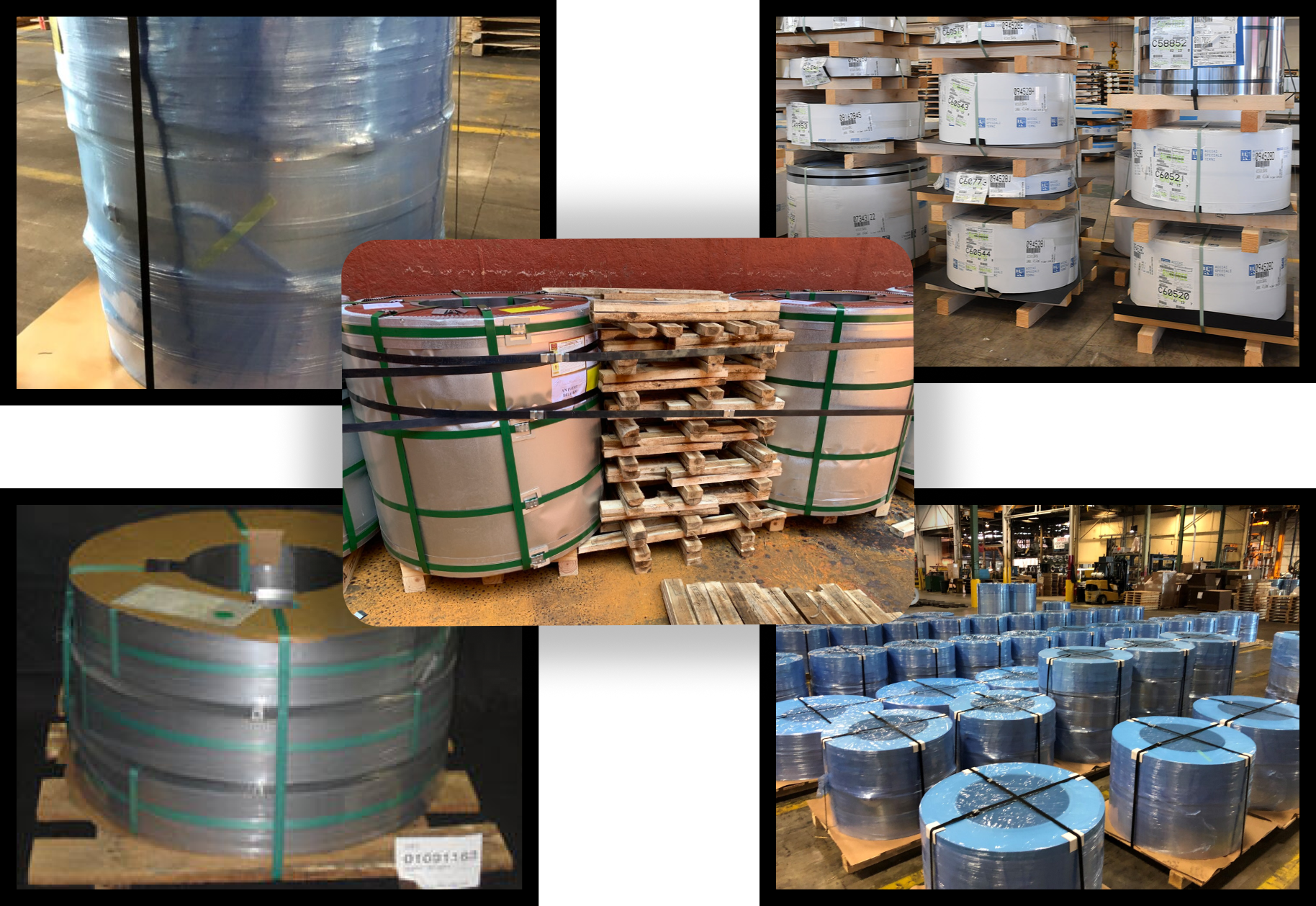

| Package | Wooden crates, Shrink-wrapped, Wooden pallets, Carton boxes, Wooden boxes, Etc. |

SS 301 Strips Equivalent Composition

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| SS 301 | 1.4310 | S30100 | SUS 301 | - | - | - | - |

Stainless Steel 301 Chemical Composition

| ELEMENT | C | Mn | P | S | Si | Cr | Ni | N |

| SS 301 | 0.150 max | 2.00 max | 0.045 max | 0.030 max | 1.00 | 16.00 – 18.00 | 6.00 – 8.00 | 0.10 |

301 Stainless steel Strips Mechanical Composition

| Tensile Strength Min (UTS) | 0.2% YS Min | Elongation% in 2” Min (50.8 mm) | Hardness Rockwell |

| 75 ksi (515 MPa) | 30 ksi (205 MPa) | 40% | 92 HRBW (Max) |

Application

Areas of Expertise:

- Heat Exchangers

- Automotive industries

- Aerospace

- Medical

- Pharmaceutical

- Oil coolers

- Economizers

- Condenser

- Pulp and paper

- Offshore construction

- Hydraulic & Pneumatic system

- Nuclear Power Plants

Packging

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as:--

- Boxes and Crates

- Shrink-wrapped

- Carton boxes

- Wooden pallets

- Wooden boxes

- Wooden crates

Testing

- Positive Material Identification - PMI Testing

- Chemical Analysis - Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

India, Brazil,Hong Kong,Switzerland, Singapore, Australia, Costa Rica, South Korea,Japan, Tibet, Nigeria, Angola, Sri Lanka, Libya, Mexico, Kuwait, Bhutan, Bulgaria, Nepal, China, Kenya, Croatia, Sweden, Trinidad & Tobago,Tunisia, Egypt, France, Bolivia, Peru, Mexico, United Kingdom, Austria, Portugal, New Zealand, Belgium, Taiwan, Poland, Macau, Israel, Serbia, Malaysia, Germany, Venezuela, Afghanistan, Ireland, South Africa, Azerbaijan, Oman, Belarus, Gambia, Saudi Arabia, Ukraine, Morocco, Greece, Spain, United Arab Emirates, Jordan, Ecuador, Nigeria, Chile, Czech Republic, Philippines, Iran, Chile, Netherlands, Canada, Namibia, Norway, Puerto Rico, Yemen, Romania, Mongolia, Slovakia, Kazakhstan, Ghana, Turkey, Finland, Lithuania, Italy, Qatar, Colombia, Russia, Lebanon, Indonesia, Bangladesh, Zimbabwe, Poland, Thailand, Gabon, Pakistan, United States, Iraq, Iran, Bahrain, Algeria, Argentina, Hungary, Denmark, Estonia, Vietnam

Jamshedpur, Rajkot, Lahore, Geoje-si, Jakarta, Kolkata, Gimhae-si, Vung Tau, Karachi, Istanbul, Manama, Kuwait City, New Delhi, Calgary, Ranchi, Muscat, Hyderabad, Mumbai, Moscow, Kuala Lumpur, Nashik, Busan, Ho Chi Minh City, Singapore, Aberdeen, Algiers, Cairo, Chandigarh, Bangkok, Indore, Rio de Janeiro, Montreal, Al Khobar, Riyadh, London, Baroda, Granada, Ankara, Ahvaz, Port-of-Spain, Caracas, Vadodara, Sydney, Thiruvananthapuram, Lagos, Pimpri-Chinchwad, Ernakulam, Nagpur, Coimbatore, Mexico City, Santiago, Abu Dhabi, Dammam, Surat, Ludhiana, Bogota, Courbevoie, Dallas, Milan, Ahmedabad, Houston, Ulsan, Visakhapatnam, Colombo, New York, Chennai, Toronto, Melbourne, Noida, Tehran, Perth, Bengaluru, Brisbane, Petaling Jaya, Jaipur, Navi Mumbai, Atyrau, Jeddah, Secunderabad, Kanpur, Gurgaon, Howrah, Hanoi, Hong Kong, Haryana, Edmonton, Los Angeles, Faridabad, Seoul, Madrid, Sharjah, Bhopal, Thane, La Victoria, Pune, Dubai, Chiyoda, Doha, Al Jubail

.webp)